A 6.4 magnitude earthquake struck Taiwan in the early hours of Tuesday (21), affecting semiconductor giant TSMC. Although the tremor caused no major damage to the company’s facilities, it forced TSMC to temporarily halt production and evacuate employees from its central and southern Taiwan factories.

The primary TSMC plants impacted included Fab 18 in Taiwan’s Southern Science Park, a key site for producing 3nm advanced lithography chips, and Fab 8, Fab 14, and Fab 15 located in Tainan and Taichung. The company reported that the strongest tremor recorded was level 5 at Fab 18, with the other plants experiencing magnitude 4 tremors.

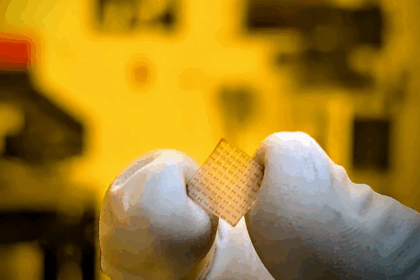

While the buildings are designed to withstand earthquakes of up to magnitude 7, the high-precision equipment used in chip manufacturing is highly sensitive and vulnerable. Despite anti-vibration systems, these machines require meticulous calibration, which may need to be adjusted after a seismic event. It is estimated that up to 20,000 silicon wafers in production at the time may have been affected by the earthquake.

How big is TSMC’s loss?

Considering that the earthquake may have damaged up to 20,000 wafers, it’s possible to estimate TSMC’s potential loss. While the exact cost of producing each wafer depends on the specific manufacturing process, a conservative estimate ranges from $3,000 to $30,000 for advanced chips. This translates to a potential loss of between $60 million and $200 million.

However, it’s important to contextualize this figure within TSMC’s overall production scale. In the last quarter, the company processed approximately 3.4 million 300mm wafers per month, averaging about 37,000 wafers delivered daily. Therefore, although the loss of 20,000 wafers is significant, it represents only a small fraction of TSMC’s total output.

Still, the costs associated with recalibrating high-precision equipment and temporarily halting production must also be factored in. However, given TSMC’s robust insurance coverage, the earthquake’s financial impact will likely be mitigated.

Other side effects

The factory shutdown was necessary not just to ensure the safety of employees but also to facilitate detailed inspections and potential recalibrations of equipment — processes that could take several days and impact delivery schedules for customers.

As for the damaged wafers, most of them will probably need to be discarded, especially those in the more critical stages of processing at the time of the earthquake. TSMC follows strict protocols for handling damaged materials to minimize losses and ensure the quality of the final products is not compromised.

Thus, it’s likely that only wafers in the early stages of production could potentially be recovered or reused, although this will depend on further technical assessments.

History of earthquakes and impacts at TSMC

This isn’t the first time TSMC’s factories have encountered earthquake-related disruptions. A similar event occurred in April 2024, leading to losses of around $92 million for the company. During that incident, equipment in areas affected by tremors of magnitude 5 or higher took about three days to return to operation.

TSMC has yet to officially disclose the full extent of the damage caused by this week’s earthquake. However, the company is already mobilizing supply chain partners and engineers from across Taiwan to carry out recovery efforts, aiming to restore production as quickly as possible.